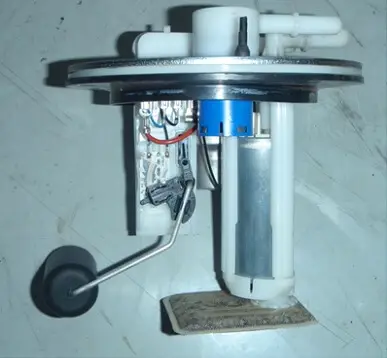

We all know that the fuel pump is like the heart of the fuel system. Without proper functioning of the fuel pump, your vehicle won’t be able to perform at its best.

The fuel pump delivers fuel from the fuel tank to the engine injectors for the combustion process. It ensures the fuel flow rate and the pressure required to lift the fuel to the engine that decides the operating performance of the vehicle.

But people often report that the fuel pump is not getting power for operation and hence the vehicle doesn’t start.

In most of the cases, it is either a bad fuel pump relay or blown up fuel pump fuse which leads to fuel pump not getting power issue. But in some cases damaged fuel pump wiring, connections or a bad ground path in circuit are also common causes for no power to fuel pump.

If you are facing the same issue, then you are at the right place! Here, in this article, you will get to know all the details required for diagnosing no power to fuel pump and how to check if the fuel pump is getting power or not? and everything you need to know!

Table Of Contents

- 1 What Is Fuel Pump Priming?

- 2 What Sends Power To The Fuel Pump Relay And fuel Pump? Where Does Fuel Pump Get Power From?

- 3 Fuel Pump Not Getting Power? How Do You Diagnose No Power To Fuel Pump?

- 3.1 Bad fuel pump wiring and terminals

- 3.2 Faulty fuel pump and ECM relay

- 3.3 Fuel pump fuse blew off

- 3.4 Bad fuel pump

- 3.5 Faulty ECM

- 3.6 No power from ECM to fuel pump relay

- 3.7 Bad cam or crankshaft position sensor

- 3.8 Reset inertia switch

- 3.9 Bad oil pressure switch

- 3.10 Faulty Ignition switch

- 3.11 Immobilizer Activation

- 4 Conclusion

What Is Fuel Pump Priming?

Before we proceed to discuss on the subject of fuel pump not getting power, it is neccesary to understand what is fuel pump priming?

We often come across the fact that, when you turn the ignition key on (not cranking/start), the fuel pump starts priming.

When we say that the fuel pump is priming, it means that the fuel pump is operated for 3 seconds before the engine is cranked to ensure that the fuel lines are filled with pressurized fuel at the back end of the injectors.

The fuel pump priming is triggered by the grounding of the fuel pump relay by the vehicle ECM (Electronic control module) for 3 seconds

After 3 seconds, once the priming is finished, the ECM ungrounds the fuel pump relay and the fuel pump stops running until it receives the crank sensor RPM signal which confirms that the cranking is performed and it has to keep the fuel pump relay grounded continuously until the vehicle is turned off.

In some vehicles, the ECM instead of controlling the ground signal to the fuel pump relay, it regulates the input voltage power to the fuel pump relay to control and activate it.

The fuel pump priming ensures that the pressurized fuel is kept ready for injection whenever we start cranking the engine.

Otherwise, the vehicle would take 2 to 3 cranks to start the vehicle. This is not a desirable situation, isn’t it?

What Sends Power To The Fuel Pump Relay And fuel Pump? Where Does Fuel Pump Get Power From?

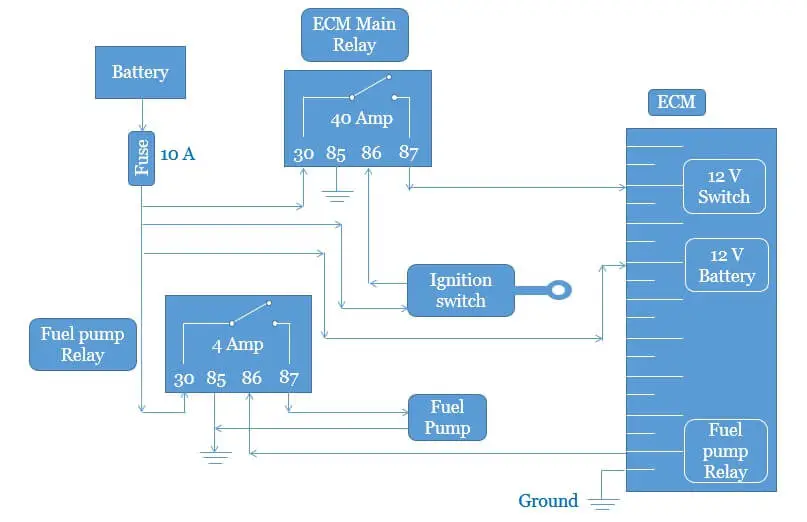

The fuel pump and fuel pump relay typically gets the power supply from the battery through a series of components and their connections starting from the fuel pump fuse, ignition switch, ECM relay, ECM, and finally fuel pump relay in that sequence.

The battery (+ve terminal) is connected to all these components. When we turn the ignition ON, the ignition switch circuit contacts close to supply power to the ECM relay which is connected in that circuit.

The ECM relay is the relay to signal the vehicle ECM. It has 4 pins representing control sides (Pin 85 (ground) and pin 86 (input voltage from the ignition switch)) and load sides (Pin 30 (battery) and pin 87 (ECM)).

When the ECM relay gets power supply from the ignition switch to the pin (86) since the pin (85) is grounded, the current will flow through (85) and (86) and the ECM relay will get energized and activate the load side by connecting the contact pins (30) and (87).

When we turn on the ignition key, the main ECM relay gets activated and closes the circuit and the power gets supplied to the ECM and flows as an input voltage to the fuel pump relay pin (86) to activate it.

Fuel pump relay also has got 4 pins (3 or 5 pins is also not uncommon). Out of these 4 pins, 2 pins belong to the control side (Pin 86 (switched on by input voltage from the ECM) and pin (85) ground) and 2 pins belong to the load side (Pin 87 (fuel pump load) and pin 30 (battery voltage, hot-wired)).

Once the fuel pump relay gets the power from the ECM through pin 86 and since pin 85 is grounded, the fuel pump relay coil is energized and activates the switch contacts to connect pin 30 (battery hot wire) and pin 87 (fuel pump) which sends power to the fuel pump.

For the current to flow through the fuel pump, it has to be grounded to close the circuit.

This series of components sends power to the fuel pump realy and pump motor and the motor starts running and supplies pressurized fuel to the engine.

Fuel Pump Not Getting Power? How Do You Diagnose No Power To Fuel Pump?

While turning the ignition key on, you would hear the typical humming noise of the fuel pump priming underneath the rear seat.

Also, if you open the fuel tank cap and listen carefully, you would hear buzzing a sound from the fuel pump indicating priming function.

If you are not getting priming sound and the vehicle is not getting started, then either the fuel pump is not getting power from the battery or the fuel pump might have gone bad.

Below are a few reasons to understand why the fuel pump would not get power in your vehicle and how to diagnose the fuel pump not getting power issue.

Bad fuel pump wiring and terminals

The first thing that needs to be done while troubleshooting the fuel pump that is not getting power is to check for bad fuel pump electrical terminals and also need to confirm no wiring damage that is routed from the fuel pump relay at the front to the fuel pump lcoated at the vehicle rear.

The terminals many times get corroded based on the environmental conditions to which they are exposed.

If the fuel pump won’t turn on with ignition, then check for corrosion at the terminal ends and replace the wiring if there is any disconnection.

While replacing the fuel pump or electrical connectors and wiring, you need to confirm the fuel pump wires color codes to avoid possible wrong wiring. Otherwise, the vehicle won’t start due to no power to the fuel pump.

How to check if fuel pump is getting power?

The fuel pump is typically mounted under the floor panel, so it is sometimes hard to reach the connector pins that supply power to the fuel pump.

In some vehicles, access cut out with lid is provided beneath the rear seat to access the terminals, but in some cars, the fuel tank needs to be dropped to access the fuel pump terminal connector pins. You may need to get your hands dirty!

To check if the fuel pump is getting power, it is preliminary to check whether the power reaches the fuel pump terminals or not.

The fuel pump won’t turn on with ignition if the fuel pump doesn’t get power from the electronic power control module at that moment.

If you follow the below procedures, you can diagnose the issue of the fuel pump not getting power and find out the root cause.

- Disconnect the connector pins at the top of the fuel pump and take a multimeter and check the voltage across the power and ground terminals.

- If the multimeter reading shows 0 V instead of 12V at the fuel pump terminal, then probably the wiring has got damaged or broken somewhere due to wear and tear

- To confirm that the fuel pump is not getting power, you may also connect the negative lead of the multimeter to a good ground in the car frame and connect the positive lead to the power terminal of the fuel pump. A reading of 0V would indicate that basically, the fuel pump is not getting power.

- In some cases, if the terminal is corroded, then you would notice voltage drop across the terminals. The multimeter will show 9 or 10V instead of 12 V which means a voltage drop of 3V. If the voltage drop is more than 1V, then it indicates corroded electrical terminals. you may need to use electrical contact cleaners to remove corrosion, if any.

Can a bad ground cause fuel pump problem? How to diagnose bad fuel pump ground?

A bad ground connection is one of the very common problems leading to the fuel pump not getting power.

It is because all parts involved like ECM relay, ECM, fuel pump relay, and fuel pump have ground connection to maintain circuit continuity.

If the issue is a bad ground, then there will not be any flow of power across the concerned parts. Since the power supply follows the typical path as discussed earlier, even if one of the parts has got a bad ground connection then it will affect the power supply to the fuel pump.

So you are gonna confirm a good ground connection from the ground feed for all the parts by using spray contact cleaners to fix the issue.

You need to perform below ground test to diagnose no power to the fuel pump. The fuel pump may be getting power but due to the bad ground connection, the circuit is not getting closed and hence the fuel pump is not getting power.

Below are the procedures to check the fuel pump ground wire is good.

- Connect the negative terminal of the battery to the negative terminal of the fuel pump connector, if the multimeter shows a reading of more than 0.5 V, then it indicated bad ground path.

- You may alternately check by connecting the battery positive to the positive lead of the multimeter and connecting the negative lead to the ground terminal on the fuel pump. The multimeter reading shall be more than 12 V, if not the fuel pump ground is bad and hence the fuel pump is not getting power.

- You can also check the resistance across the fuel pump terminals. If the multimeter shows infinite resistance instead of 0 ohms, then it again confirms that there exists a bad fuel pump ground.

By following the above steps you will get to know whether the fuel pump is getting power or not.

To ensure that the fuel pump is getting power while checking the voltage, someone needs to crank the engine otherwise the fuel pump will not get 12 V power in that circuit from the ECM.

This is particularly true if the fuel pump priming arrangement (pump running for 3 seconds) in the ignition ON condition is not available for the pump.

If you have a fuel priming function in your vehicle, then there is no need to crank the engine. You can measure the voltage when someone puts the key in ignition on mode.

Need to measure the voltage again? Then put the key ‘OFF’ and then back to ‘ON’

You also need to measure the voltage across the various terminals of the fuse, fuel pump relay, main relay, and ECM to check where the power is being fed in that circuit.

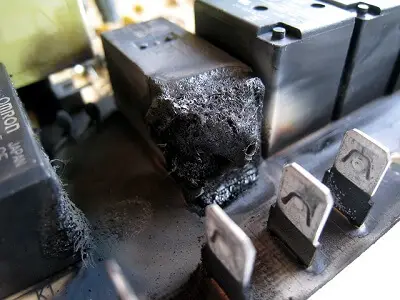

Faulty fuel pump and ECM relay

As discussed earlier, the fuel pump relay is the component that sends power to the fuel pump. But what if the fuel pump relay turns faulty?

This would mean that the coil inside the relay has either got damaged and would not produce a magnetic field to activate the relay switch. Also, maybe the contact switch has got corroded and turned poor conductor of power to the fuel pump.

If the fuel pump relay goes bad, the fuel pump won’t turn on with ignition. In this case, any number of times to start the vehicle by turning on the ignition key will not help.

The issue will persist unless the bad fuel pump relay is replaced by a new one.

The same logic can be applied to the ECM main relay, a bad one will prevent the fuel pump from getting power.

Swap the relays

If you happen to work under the hood, you would have seen the TIPM box (Total Integrated Power Module) which contains various relays and fuses.

Typically, many relays of the same ratings are used for different applications like A/C relay, window relay, park lamp relay, etc,

To diagnose no power to fuel pump, pull out the fuel pump relay from its socket and use other relays of the same rating in place of the fuel pump relay to confirm whether the fuel pump relay has gone bad and not sending power to the fuel pump.

Ensure that the other relay is not linked to any of the engine fuel systems otherwise the vehicle won’t start.

Bypass fuel pump relay

You can jump the fuel pump relay and see if you have power to the fuel pump. Simply connect the load side pins 30 and 87 together by using a jumper wire.

If the issue is due to faulty fuel pump relay coils, then the fuel pump shall start running after the jump.

The fuel pump won’t prime in this case and it will run continuously even when the vehicle is off. So this is a temporary fix until you replace the fuel pump relay with a new one.

Article you may like to read “How To Bypass Fuel Pump Relay? Everything You Need To Know!“

Fuel pump fuse blew off

Have you checked the fuel pump fuse? The blown-up fuel pump fuse is often reported to be the main reason for the fuel pump not getting power.

There are various fuses used in the cars connecting the components like the fuel pump and ignition switch.

If the fuel pump is failing it would work hard and draw heavy current to overcome the internal resistance.

The heavy current would start heating up the element in the fuel pump fuse and would blow it off, so the fuel pump won’t turn on, since the blown fuel pump fuse won’t allow power to the fuel pump.

Some cars have a fuel pump circuit breaker instead of a fuel pump fuse to cut off the heavy current from damaging the fuel pump.

Fuel pump circuit breakers usually have a button on top that pops up when it trips and will not allow the fuel pump from getting power.

Article you may like to read “Fuel Pump Fuse Keeps Blowing? 9 Causes And Solution To Fix It!“

Identify and replace fuse

Are you checking the right fuse for the fuel pump before diagnosing other parts?

Even though it sounds obvious, people often mistake other fuses for fuel pump fuses. Typically, the fuel pump fuse rating is 10 amp.

The fuel pump fuse may be blown but since you have checked the wrong fuse, you lost the opportunity of fixing the issue of the fuel pump not getting power.

It is common to have a fuse go out in case of a failing fuel pump. Hence it is essential to identify correct fuse and replace it with a new one, if the fuse is blown-off.

Push back circuit breaker

Simply push this button back until it clicks. You may refer to the owner’s manual to find the location of the circuit breaker if you are not able to find one.

Bad fuel pump

Are you concluding that the fuel pump is not getting power since you don’t hear the humming sound of fuel pump priming?

It is very much possible that you have plenty of power going to a failed fuel pump. The fuel pump won’t turn on with ignition if the fuel pump itself is bad.

If you measure 12V at the fuel pump connector terminals and still the fuel pump is not running, then you wanna replace the fuel pump with a new one.

Diagnose wiring harness

Just unplug the harness connected to the fuel pump terminals and then connect the battery directly to the positive power wire of the fuel pump to diagnose no power to the fuel pump.

If the fuel pump doesn’t come alive even after connecting to a direct power source, then the fuel pump has gone bad and needs to be replaced with a new one.

If the pump operates and supplies pressurized fuel to the engine, then there is an issue with the power supply to the fuel pump when connected to the vehicle harness.

Maybe it is the damaged wiring harness!

Article you may like to read “Car Won’t Start After Fuel Pump Replacement? All You Need To Know!“

Faulty ECM

If the fuel pump relay is working fine, then the faulty ECM can be one of the reasons for the fuel pump not getting power.

The ECM is supposed to either ground the fuel pump relay or supply power to it, once it gets the signals from the ECM relay after the ignition switch is turned ON.

But if the ECM itself is faulty, it will neither supply power to the fuel pump relay nor ground it for maintaining circuit continuity, hence the fuel pump won’t get power for its operation.

We know that the fuel pump gets power supply from the ECM which in turn gets power from the ECM relay which gets activated when you turn on the ignition key. But if the ECM malfunctions, then the fuel pump won’t turn on with ignition.

Swap ECM

You may try swapping the new ECU (or some spare ECU from a friend) in place of the bad ECU to troubleshoot no power to the fuel pump and see whether the fuel pump receives power.

If yes, then you would need to replace the ECM with a new one.

In some cases, the output transistor of the ECM use to get bad over a period of usage. You may check, is there any broken wire on the terminal which is connecting the fuel pump relay to the printed circuit board PCB of the ECM.

If it is the case of a broken terminal, then you may try soldering the terminals if you are a DIY kind of guy.

Jump fuel pump relay load pins

As we know the fuel pump relay is controlled by the ECM electrical signals.

The easiest way to confirm that the ECU is the problem area is by removing the relay from its socket and using a jumper wire to jump the pins 30 (battery, hot wire) to pin 87 (fuel pump load) to connect it together.

You would notice that the fuel pump runs only when you jump, indicating that the faulty ECM is not allowing the fuel pump from getting power.

No power from ECM to fuel pump relay

It is apparent that if there is no power from ECM to the fuel pump relay then the fuel pump also will get power.

Bad ECM terminals and connections

To diagnose the case of no power to the fuel pump, connect the negative lead of the multimeter to a good ground on the vehicle chassis frame and connect the positive lead of the multimeter to the ECM.

If the reading shows 0 V, then the power is not reaching ECM and there will be no power from ECM to the fuel pump relay to supply power to the fuel pump.

The wiring harness that goes from ECM to the fuel pump relay has got many electrical connection points.

One is coming from the battery to the ECM at the ECM end, the second is the connection that starts at the ECM and the third one ends at the fuel pump relay. Ensure that these connections are not loose and also not corroded.

The corrosion affects the power conduction and causes no power supply from ECM to the fuel pump relay. You may try using spray cleaners to clean the electrical connections.

Bad cam or crankshaft position sensor

The fuel pump won’t get power if you have a bad cam or crankshaft sensor. You may ask, what is the connection between the crankshaft sensor and the fuel pump?

If the cam or crank sensor goes bad, it either won’t sense the engine RPM or even if it senses it would not give the signal to the ECM, as if there is no RPM.

But in reality, if the engine is trying to run, then the wrong input from the cam or crankshaft sensor would force the ECM to unground the fuel pump relay (which otherwise has to be kept grounded) and would disconnect the power supply to the fuel pump.

This issue is especially true when your pump receives power while it primes for 3 seconds when the ignition is on, but the fuel pump doesn’t get power while cranking the engine.

In this case, we would not blame the ECM for the fuel pump not getting power. But many times, we do! Isn’t it? So, inspect and replace the bad cam sensor if is found to be the culprit.

Reset inertia switch

When the fuel pump is not getting power, we troubleshoot many related components but the problem could be as obvious as a safety shut-off switch, switching off the fuel pump.

Typically, there is an inertia safety switch that opens when you run into an impact on your vehicle. Since the fuel pump gets power through the inertia switch unless you reset this safety switch the fuel pump won’t turn on with ignition.

Jump inertia switch

You can just jump the terminals of the inertia switch to diagnose no power to the fuel pump by connecting the wiring harness that comes from the fuel pump relay directly to the fuel pump to confirm that the fuel pump not getting power due to the triggering of the inertia switch which breaks the electrical circuit.

Bad oil pressure switch

Many vehicles have oil pressure switch instead of an inertia switch as a safety device.

The battery supplies power to the 15A fuse which in turn provides power to the Oil Pressure Switch and the fuel pump relay which are connected in parallel in the circuit.

If Oil Pressure Switch goes bad or the oil pressure reduces to an undesirable level, the power supply to the fuel pump will be cut and the fuel pump won’t run. Otherwise, the engine will self-destruct if the oil pressure reduces abruptly.

In many of the old models, the fuel pump gets the power supply through the oil pressure switch once the engine oil pressure reaches desired pressure (say 10 psi) in addition to getting the electric feed from the fuel pump relay.

If the fuel pump relay fails, the fuel pump still gets power through the oil pressure switch circuit. Either one can activate the fuel pump.

But if both the fuel pump relay and oil pressure switch go bad, then the fuel pump wont turn on with ignition and will not get power unless the oil pressure switch is replaced by a new one.

Faulty Ignition switch

The ignition switch is one of the major components which control the power supply to the fuel pump and the fuel pump relay.

Have you checked the ignition switch? It could go bad after some operations and would cause ignition issues in the car.

As discussed earlier, since the power to the fuel pump is fed through the ignition switch, via. the ECM relay and the ECM, a faulty ignition switch would mean no power to the ECM relay and that would mean no ground/input voltage to the fuel pump relay through the ECM and hence the fuel pump won’t turn with ignition has the pump won’t get power. Hence Inspect the ignition switch and replace it, if found faulty.

Immobilizer Activation

The Immobilizer is an antitheft device that prevents the movement of the vehicle if someone tries to steal your vehicle.

Are you getting any immobilizer activation pop up on your dash panel?

If yes, then your fuel pump will not get power in those vehicles since these antitheft devices disconnect the electrical circuit that supplies power to the fuel pump.

Conclusion

Fuel pump not getting power is one of the key problems which is often faced by the people.

Since the fuel pump receives power after traversing several components and meeting certain circuit requirements, it seems almost difficult to diagnose no power to fuel pump, but it is not that complex either!

It is even possible that the fuel pump is getting power but it is not allowing the power to flow across it due to the bad ground path or the power is being sent to a bad or failing fuel pump which you mistake as fuel pump not getting power.

I have tried to collate all possible reasons which could lead to the fuel pump not getting power issue and how to diagnose the electrical circuit that sends power to the fuel pump.

If you follow the diagnosis discussed honestly, hope you will troubleshoot the fuel pump not getting power issue and can find the root cause of the problem.

Happy motoring!

References

http://www.nsxprime.com/forum/showthread.php/187137-Engine-crank-no-start-no-power-to-fuel-pump

https://www.2carpros.com/questions/no-power-to-fuel-pump-both-relay-fuse-good-changed-fuel-pump

https://www.thelotusforums.com/forums/topic/113414-fuelpump-no-power/

https://community.cartalk.com/t/no-power-to-the-fuel-pump/23103

Related Articles

Silverado Fuel Pump Control Module Bypass? Everything You Need To Know!

Car Stalls in reverse? 9 Reasons and solutions to fix it!

Fuel Pump Not Priming? Reasons And Solutions To Fix It!

Fuel Pump Primes But No Pressure? Everything you Need To Know!

Fuel Pump Runs Continuously With Key On? (9 Causes And Solutions To Fix It!)

Can A Fuel Pump Go Bad From Sitting? Everything You Need To Know