Whenever there is a vehicle not starting or sputtering issue, people often anticipate issues related to the fuel system in the vehicle.

Since the fuel pump is like the heart of the vehicle whose responsibility is to pump the fuel to the engine, it is quite natural to anticipate concerns related to it.

When the engine doesn’t receive enough fuel at the required pressure, the vehicle either won’t start or there will be a sputtering issue eventually the car would stop during driving.

When people experience vehicle-related issues and think of replacing either the fuel filter or fuel pump, the question that arises is whether the fuel filter shall be placed before or after pump.

It is essential to have a coarse fuel filter before pump in case of an in-tank electric pump to keep tank contaminations at bay and a fine fuel filter after pump to prevent the entry of fine dust particles and trashes into the engine parts like carburetors and fuel injectors which are sensitive to dirty foreign particles.

If you are also facing vehicle issues and are interested to know where a fuel filter shall be installed, you are in right place! Stay tuned for more details!

Table Of Contents

Fuel Filter Before Or After Pump? Which One Is Correct?

The answer to the query of whether to locate the fuel filter before or after fuel pump depends on the type and quality of fuel filter (fine or coarse), fuel pump, how genuinely you are following the periodic maintenance schedule for fuel filter inspection and replacement, and quality of fuel available at your place.

1. In-tank Electric Fuel pump

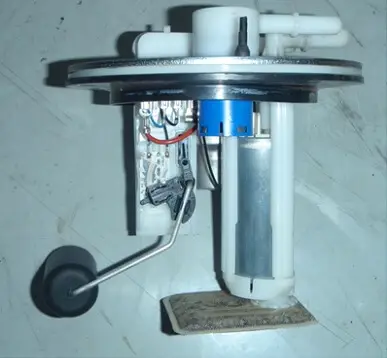

In modern vehicles with a fuel injection system, the fuel pump is typically an electric in-tank mounted module and has brushes and commutators arrangement.

Here, the fuel pump itself would create debris due to the continuous make and brake brush contact, hence a fine fuel filter after pump is needed to filter the pump-generated debris and ensure clean fuel supply to the engine parts like carburetor or fuel injector and throttle body.

In many cases, the fuel pump or fuel tank is packaged at a critical location on the vehicle and it becomes difficult to access the fuel pump to clean or replace the fuel strainer, hence a fine fuel filter is placed after the in-tank pump somewhere on the chassis or underbody which is easily accessible and replaceable without need to remove fuel tank assembly.

In addition to a fine fuel filter after pump, it is necessary to have a coarse fuel filter before pump (also called straining filters or pre-pump filters) to protect the fuel pump impellers from coarse debris, trash, and fuel contamination due to tank rusting and at the same time allow huge fuel flow rate without any pressure drop.

Otherwise, these foreign particles will find their way into the fuel pump and would damage the impeller blades and would increase the clearances between the impeller units and leads to less fuel discharge and pressure.

The straining filters are typically not part of periodic maintenance, but if there is an issue with the fuel flow and vehicle performance, you may like to check the condition of the same.

The mesh size of a coarse fuel filter is typically around 80 microns and these pumps are typically designed to withstand dust particles of size less than 80 microns; hence the pump won’t get damaged.

Having two filters (fine and coarse) would not affect fuel pump operations, since the pressure generated by the fuel pump is far more than the pressure drop offered by the fuel filters put together.

2. Brushless In-tank Fuel Pump

In the case of a brushless fuel pump for an EFI system, typically called a BLDC fuel pump, the fuel pump won’t create any debris and it is not essential to filter the fuel past the fuel pump hence you may notice that there is no fuel filter provided by the vehicle manufacturer after the fuel pump in case of BLDC fuel pump.

This in-tank mounted fuel pumps are not good in suction hence they are dipped inside the fuel and supply pressurized fuel to the fuel injectors in downstream.

But it is worthwhile to note that in this case, the fuel pump shall have an inbuilt fine fuel filter before the pump at the pump suction side to filter both fine fuel contaminants and coarse rust or foreign particles present in the tank.

The fine fuel filter is often made of non-woven fabric and the aperture size is typically around 10 microns which shall be sufficient to capture fine dust particles which vary from region to region depending upon the quality of the fuel available in that region.

The fine fuel filter shall have a high flow rating to compensate when the filter mesh starts clogging in usage.

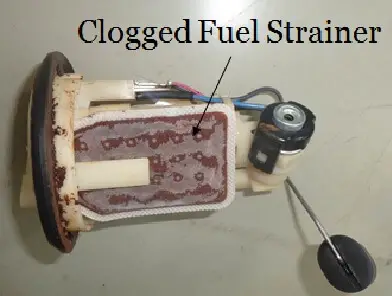

But here there is a risk of fine fuel filters getting clogged up and increase pressure drop which may lead to cavitation and vapor lock phenomena since the prevailing low-pressure conditions reduce the boiling point of fuel and cause fuel vaporization.

The clogging of the in-built fuel filter before pump would lead to dust entry into the fuel pump and damages it thereby reducing the fuel flow rate and pressure to an extent you would notice vehicle power loss and sputtering issue, especially during acceleration as a result of fuel starvation.

Hence a fine fuel filter before pump alone will not suffice. But if the fuel filter is frequently serviced (say at every 10000 miles), there shall not be any issue.

It is easy and cheaper to clean the fine fuel filter or replace it than to replace the fuel pump if it gets damaged by the tank trash.

Replacing this fine filter after the pump failure won’t reinstate the fuel pump to its original running condition, as the dust particles would cause irreversible damage to the fuel pump and the car won’t start even after replacing fuel filter.

So, note that the fuel pump once damaged, failed forever. Sometimes the damaged fuel pump may supply fuel with the required pressure temporarily and the vehicle seems to run fine, but the performance may go down at any moment and we can’t guarantee that the fuel pump will perform consistently.

This is because as the fuel pump runs, the dust particle location inside the fuel pump keeps on changing, and at some moment it may block the fuel flow path and momentarily the fuel flow and pressure gets affected and this is sufficient to stall the vehicle or make it sputter or lose power.

In many in-tank electrical fuel pumps, the fuel pump has a vapor jet hole to release the air trapped inside the fuel pump when the fuel level inside the fuel tank goes below the pump suction level.

This vapor jet hole is usually at positive pressure than the surrounding fuel inside the fuel tank, so there is no question of unfiltered fuel getting sucked inside the fuel pump through this vapor jet hole.

But when the fine fuel filter on the suction side gets clogged, the fuel pump will try to suck the fuel, thereby it creates negative suction pressure at the vapor jet hole location and this causes entry of unfiltered fuel directly into the fuel pump and thus damages it.

Hence it is necessary to inspect and replace the in-tank fine fuel filter placed before pump at frequent intervals as per the vehicle manufacturer’s guidelines to avoid costly fuel pump replacement operations.

Many vehicles or fuel pump manufacturers do not accept a warranty if your vehicle does not have a fine fuel filter before pump, as it is a pre-requisite for the pump function.

3. Inline External Fuel Pump

In the case of an external lift pump that is electrically operated, it is recommended to have a coarse fuel filter before the fuel pump to protect the pump from coarse dust particles and it shall allow fuel without much pressure drop.

Moreover, the electric fuel pump is not that good in suction if it has a large pressure drop or restrictions.

If we use a fine fuel filter before pump and there will be a large pressure drop, and if there is a high-temperature condition, then there is a possibility of vapor lock due to reduced boiling point caused by low working pressure.

The external electric inline fuel pumps are usually robust enough to withstand foreign matters in the fuel and hence a coarse fuel filter before pump would work, but a fine fuel filter after pump is also required to supply clean fuel to the engine parts which are not as robust as the fuel pump.

In the case of the mechanical fuel pump, since the pump suction is very low and shall have minimum restrictions on the suction side and also there are chances of rubber diaphragm getting damaged and reaching the engine parts, it is advised to have a fine fuel filter after pump to protect the dust sensitive engine parts as the mechanical pumps are typically not that affected by contaminants in the fuel.

When the fuel filter is placed after the fuel pump, the fuel pressure at the fuel pump outlet will be higher and the fuel filter would introduce a pressure drop and put a load on the fuel pump delivery side.

Conversely, when the fuel filter is before the pump, the less pressurized fuel due to the pressure drop effect introduced by the fuel filter would reach the fuel pump and it would need to work more for the fuel suction and then to pressurize the fuel to ensure fuel flow rate. If the fuel filter is coarse, the pressure drop effect may not be that high and there will not be any issue.

It is worthwhile to note that when the fuel filter is placed after pump, the paper filter matrix would be exposed to high pressure which may affect its performance and may damage it depending on the type of fuel filter material and this may lead to escape of dust particles to the engine which may clog the fuel injectors and vehicle may get stalled or start sputtering.

If we do not protect the fuel pump by having a coarse fuel filter before pump, the pump may get damaged and it depends on the robustness of the pump.

The fuel pumps are usually designed considering the pressure drop exerted by the fuel filter either on the upstream or downstream side or both. So, it is better to follow what is provided by the OEMs as a part of the package.

The fuel filter placement matters a lot, especially in modern vehicles where a fuel injection system is predominantly used which calls for sophisticated fuel injectors and other parts.

The system is not that complex in older carburetor versions, where the fuel just needed to be fed to the carburetor bowl, having pressurized fuel, creates an issue in carburetor versions.

Any dust particles, if it reaches the engine would get accumulated at the bottom of the carb bowl. Even if the dust entangles at the carb needle, the openings of the needle are sufficient enough to discharge the dust particles with a typical hiss sound.

Conclusion

People often blame the fuel filter for vehicle stalling or sputtering or pump noise issues but the real problem sometimes lies with the fuel pump.

The fuel pump owing to its durability life undergoes wear and tear and produces noise after some mileage of running, hence proper inspection of the fuel pump and the quality of fuel remaining inside the fuel tank and the condition of the fuel tank (rusting) are necessary to conclude the problem area.

It is recommended to install a coarse fuel filter or strainer filter before pump and a fine fuel filter after the pump.

To keep the tank rust flakes or contamination at bay, you need a screen kind of coarse fuel filter before pump and to trap the fine particles, your vehicle would need a fine fuel filter after the fuel pump.

This is especially true in the case of the traditional in-tank electric fuel pump (non-BLDC) and external fuel pump mounted on chassis.

In the case of an electric in-tank BLDC fuel pump, a pre-pump fine fuel filter is placed at the suction side of the fuel pump and no fuel filter is required after pump.

But you run the risk of the filter getting clogged but it will not be an issue if you are following periodic maintenance as per schedule.

If the fuel filter placed before pump gets clogged, cleaning or replacing the fuel filter will be a cost-effective option compared to that fuel pump damage and replacement.

If the vehicle manufacturer has designed a fuel system configuration with certain considerations like fuel filter and fuel pump robustness, then that need to be respected.

The troubleshooting and decision depend on the type of fuel pump and fuel filter being used and the working conditions which the fuel pump is designed to withstand without durability issues.

Happy Motoring!

References

https://www.pistonheads.com/gassing/topic.asp?h=0&f=26&t=1378336

https://www.camaros.net/threads/fuel-filter-before-or-after-mechanical-pump.181706/

https://www.lrukforums.com/threads/inline-filter-before-or-after-pump.259237/

Related Articles

Fuel Pump Vs Fuel Filter? How to Identify Problems?

Car Won’t Start After Fuel Pump Replacement? All You Need To Know!

Fuel Pump Primes But No Pressure? Everything you Need To Know!

Fuel Pump Not Priming? Reasons And Solutions To Fix It!