Whenever you have trouble associated with engine performance in your car, often it roots down to issues in one of the fuel system components like the fuel pump, fuel filter, fuel pressure regulator, fuel injector, fuel injection pump, and fuel common rail system.

Typically, these parts need to be inspected and maintained periodically to avoid sudden issues in your vehicles like engine starting or engine stalling problems.

These fuel system components play a foremost role in ensuring the fuel reaches the engine to keep your vehicle running.

Since there are various parts involved to keep the engine ticking, even a professional mechanic would get perplexed to zero in on the problem item.

A well-trained mechanic would use the technique of elimination to find out the root cause of the problem by testing each and every component involved by inspecting parts one after the another.

It is observed that people often get confused when it comes to which part to target to resolve the engine performance issues associated with fuel system components, especially the one between the fuel pump and fuel filter.

If the fuel pressure at the fuel pump outlet is within specifications as per the vehicle manufacturer then the issue would be with the clogged fuel filter in the fuel circuit. If the fuel pressure is the problem, then you need to troubleshoot the fuel pump.

If you are also looking for details of the fuel pump and fuel filter, then this article is for you. Here, we will explain the Fuel Pump Vs Fuel Filer and how to identify problems associated with it.

Table Of Contents

Fuel Pump

The fuel pump is like the heart of the fuel system. Its key function is to pump fuel to the engine with the predetermined fuel flow rate at desired pressure through fuel supply hoses.

If you take any vehicle, the fuel system involves usage of any one of the types of fuel pumps like an in-tank fuel pump, external fuel pump, and high pressure fuel pump. All these pumps have one thing in common, i.e. ensure fuel reaches the engine from the fuel tank.

Function and Location

In-tank fuel pump

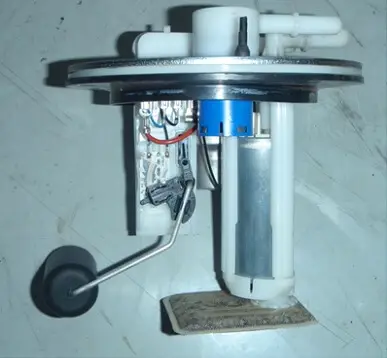

The in-tank fuel pump is usually immersed inside the fuel in the fuel tank and positioned on the top of the fuel tank that is located underneath the floor panel of the vehicle.

The key role of an in-tank fuel pump is to pull fuel from the fuel tank and supply it to the engine at the required pressure (say 3 bar).

In the case of gasoline vehicles, the in-tank fuel pump pressurizes fuel to lift it up to the engine and also ensures fine atomization of fuel at injectors. Here no additional high pressure fuel pump is required.

The in-tank fuel pump module typically has an inbuilt fuel strainer or filter, electric motor, pressure regulator, and a non-return check valve.

The fuel pump’s electric motor has impellers or roller cells that suck fuel through the filter or strainer on the suction side to filter out the contaminants and generate pressure on the discharge side by centrifugal action and supplies filtered and pressurized fuel to the engine.

The fuel pump’s pressure regulator serves the function of regulating the fuel pressure being delivered to the engine. Once the pressure reaches set pressure, the pressure regulator leak backs the fuel into the fuel tank.

External fuel pump or Lift pump

Diesel vehicles have an inline external fuel pump or lift pump which functions similar to an in-tank fuel pump.

The only difference is, it is fitted on the chassis of the vehicle and not inside the fuel tank.

It lifts the fuel from the fuel tank and supplies it to the high pressure fuel pump mounted on the engine at a higher position. It does this operation either by reciprocating or centrifugal motion.

High pressure fuel pump

In the case of diesel vehicles, apart from the lift pump, the engine has high pressure fuel pump driven by the engine via a drive shaft.

This high pressure fuel pump is capable of developing very high pressure of the order of 130 to 150 psi.

The vane pump rotor inside the pump creates a vacuum and draws fuel via. the fuel hoses from the fuel tank, then pressurize and discharge to the fuel injectors located close to the intake valves.

The fuel discharge of the vane pump is controlled by a set of parts like a metering valve, throttle response mechanism, governor weight retainer arrangement, etc.

Activation condition

In-tank and External fuel pump

The fuel pump gets the input signal from the vehicle’s computer (ECU) and permits the power supply to the fuel pump by grounding it.

This activates the motor of the fuel pump and through centrifugal action, the pressurized fuel is discharged out of the fuel pump.

Initially, the fuel pump is activated for 3 sec, when the car key is kept in the ignition ON position, and then it is stopped.

This process is called fuel pump priming which is meant to keep the fuel supply hoses pressurized before the engine is cranked by putting the key in START position.

High pressure fuel pump

In the case of a diesel engine, the drive shaft of the fuel pump is driven by the engine through governor weight retainer and fuel metering arrangement which in turn is controlled by the accelerator throttle response.

When the engine RPM is low or idling, the metering valve is closed. But when the engine RPM and fuel demand increase, the metering valve connects the vane pump outlet to the fuel injectors.

Thanks to the governor weight retainer arrangement which comes into action due to the centrifugal forces.

Malfunction outcome

In-tank fuel pump

The in-tank fuel pump functions properly as long as there is no accumulation of foreign particles inside the suction strainer or impeller bucket blades.

Predominant failure mode which is usually reported in the fuel pump is the pump’s inbuilt filter or strainer clogging.

This stems from the fact that the fuel strainer is located close to the fuel tank bottom surface where there is a large possibility of foreign particles getting settled and sucked by the strainer thereby clogging itself.

Clogging of the filter or strainer reduces the fuel pump performance specifications resulting in low delivery pressure and flow rate.

An impeller is generally placed between inlet and outlet side plates. The presence of the dust particles would wear the impeller surfaces and increase the gap between the impeller blades and the inlet/outlet plates.

This gap is critical for fuel delivery pressure and fuel flow rate. Any change in the gap would impact the pump performance and generally manifests in the form of engine misfire, engine hesitation while acceleration, poor throttle response, and vehicle hard starting problems unless the fuel pump or strainer is replaced with a new one.

You may like to read “Fuel Pump Primes But No Pressure. Everything You Need To Know!“

External fuel pump Or Lift pump

In the case of the lift pump, since it is mounted on the outside of the fuel tank, fuel pump inbuilt strainer or filter clogging is not the issue here.

But as it is not immersed inside the fuel, heat generated during the running would be carried away only by the air flowing across it.

Hence the durability life of the lift pump would be comparatively less than an in-line fuel pump and causes vehicle starting problems and poor throttle response over some period of running.

Replacing the lift pump with a new one is required if you face engine performance-related issues.

High pressure fuel pump

Often the in-line fuel pump or lift pump failure occurs before the high pressure pump does. Ensuring proper maintenance of feed pumps will prolong the life of the high pressure pump.

As the vehicle ages, the high pressure fuel pump will encounter wear and tear and its performance reduces and would result in engine misfire, poor throttle response, and vehicle hard starting issues.

The high pressure fuel pump usually lasts for a long time and seldom requires replacement which depends on the fuel quality being used.

Servicing

The servicing of the fuel pump involves the tedious task of dropping down the fuel tank that is mounted underneath the vehicle floor panel.

Once the tank is removed, then unscrew the fuel pump mounted on top of it. You need to note down the orientation in which the pump is mounted so that there will not be any issue while refitting the fuel pump.

Otherwise, there is a possibility that the fuel level sensor’s float may foul with the surrounding wall of the fuel tank and would lead to incorrect fuel indication on the dashboard.

Replacing a fuel pump is a costlier affair since the cost of the pump itself ranges from $200 to $800 depending upon the make of the pump and the labor cost would be around $125 to $250. So the overall fuel pump replacement cost would be around $300 to $1000.

In some vehicles, the fuel pump is easily accessible through an access window provided beneath the rear seat. Remove the access cover and simply disconnect the quick fix fuel lines from the fuel pump and pull out the fuel pump from the fuel tank.

Fuel Filter

Function

The fuel filter is like the kidney of the vehicle whose main role is to filter the fuel being sent to the engine.

The dust holding capacity of the fuel filter is the parameter that defines the capability of the fuel filter to store dust particles without much affecting the fuel pressure.

An efficient fuel filter is the one that holds a large amount of dust particles without a significant pressure drop across it.

It does this operation by trapping the foreign particles on the paper or mesh or woven fabric layers in it.

The gasoline filters are usually small in size but the diesel filters are relatively bigger and often have bowl arrangements.

Modern diesel filter also has water separator provision and the water needs to be removed as and when it gets filled up and usually have temperature sensors inbuilt in it.

Location

Basically, there are two types of the fuel filter. One which is fitted externally on the vehicle chassis is called the in-line fuel filter and the one which is inbuilt with a fuel pump module is called a strainer.

The placement of fuel filter or strainer is of prime importance. People often get confused whether the fuel filter to be placed before or after pump for best pump performance, but this depends on type of fuel filter, mesh size and type of fuel pump.

Malfunction outcome

The fuel filter shall filter fuel as long as it reaches its dust holding capacity. Any further accumulation of foreign particles would mean that it will reduce the pressure at which the fuel is sent to the engine and also reduce the fuel flow rate.

Often the filter media is observed to be degraded after some period of use and the dust particles get past the filter and find their way to the engine and clog the fuel injector and other engine components.

This sometimes causes scoring marks on the piston and cylinder, thereby affecting the engine performance.

All these leads to improper fuel injection, combustion and hence would result in problems like engine misfire, stalling, hesitation, poor throttle response, check engine light activation (CEL), and engine emission failure.

Servicing

The fuel filter which is mounted near the engine bay area or underneath the floor panel is relatively easy to access and service.

But if the in-built filter or strainer of the fuel pump needs to be replaced, then it would be a pain in the butt and you would need to shell out more bucks for the same job.

Depending upon the complexity of the job involved the labor cost will be in the range of $50 to $100 and the fuel filter cost itself would be somewhere between $20 to $50. So the overall fuel filter replacement cost would be around $70 to $150.

Frequently Asked Questions

Can a bad fuel filter cause fuel pump problem?

Yes, when the fuel filter gets completely clogged up, it creates a large pressure drop across it. This puts undue load over the fuel pump which needs to work hard to develop the same pressure when the fuel filter was working fine.

Over a while, the fuel pump durability life would get affected and the fuel pump fuel flow rate and discharge pressure reduce to such an extent that you would be able to notice the engine performance issues like pickup or power loss, etc.

Even the clogged fuel filter begins to dislodge the foreign particles towards the engine and ends up blocking the fuel injector. This as you know would give rise to a host of issues related to it.

How do you tell if your fuel pump or fuel filter is bad?

Do you remember replacing the fuel filter recently? If not, then it’s time to replace it with a new one. Fuel filter needs to be periodically replaced at least once in 25000 miles or as per vehicle manufacturers handbook.

Since replacing the fuel filter is inexpensive, it is recommended to do so periodically to avoid sudden surprises while driving your car.

If you have already replaced the fuel filter a while ago, then it is time to inspect the fuel pump thoroughly.

Preliminary checks can be done without even removing the in-tank fuel pump. This can be done by removing the fuel cap and listening carefully to the hissing sound inside the fuel tank while someone turns the ignition key ON.

This is actually the sound of priming of the fuel pump which one would hear while switching ON the ignition of the car.

You can listen to the hissing sound coming from underneath the car below the rear seat of the car if the fuel pump is mounted over there.

If you are not able to hear any humming sound, then drop the fuel tank and pull out the fuel pump and connect a fuel hose and T-connector to the outlet nozzle of the fuel pump.

Connect a pressure gauge to one end of the T-connector and plug the other end. Start cranking the vehicle or provide an external power supply to the fuel pump electrical connectors.

You shall be able to measure the maximum block condition or shut-off pressure of the fuel pump on the pressure gauge.

If the gauge readings meet the specifications as per the vehicle manufacturer, then the problem is not the fuel pump, it may be the fuel filter or some other components of the engine and vice versa if the readings are below specs.

If you don’t have a pressure gauge, simply check the fuel pressure by pressing the thumb on the outlet nozzle of the fuel pump.

If you couldn’t feel the fuel pressure on your thumb or if the visual observation indicates the flow rate is very less, then the fuel pump is the culprit.

Final Thoughts

Fuel pump and fuel filter play a key role in the working of the internal combustion engine and ensure proper vehicle performance.

The fuel pump pressurizes the fuel and sends it across the fuel filter wherein the fuel is filtered to make it suitable for supplying to the fuel injectors.

Whenever there is a malfunction of either fuel pump or fuel filter, you would end up experiencing vehicle-related problems sooner or later and the concerned parts needs to be fixed before it creates chaos.

Hope from the above comparison of Fuel Pump Vs Fuel Filter, you would have understood the functions performed by these components, where it is located and malfunction outcome, etc., and the dependency of fuel pump over the fuel filter for its performance.

Fuel pump and fuel filter are entirely two different parts and each has some separate role to play in the fuel system. Hence it is easy to troubleshoot the issues related to these parts and identify associated problems.

Happy motoring!

Related Articles

Fuel Injector Vs Fuel Pump? How It Differs?

Fuel Pump Not Priming? Reasons And Solutions To Fix It!

Car Won’t Start After Fuel Pump Replacement. All You Need To Know!

Fuel Pump Primes But No Pressure. Everything You Need To Know!

Fuel Pump Runs Continuously With Key On? (9 Causes And Solutions To Fix It!)

Fuel Pump Fuse Keeps Blowing? 9 Causes And Solution To Fix It!