If you happen to visit a fuel filling station to fill up the gas in your vehicle, then it is normal that you may occasionally end up spilling the fuel out of the fuel filler neck.

I bet sometimes you might have shouted at the fuel station guys to complain about the bad fuel filling dispenser nozzle! Has this happened to you?

When the gas station guys tell you that this issue doesn’t happen for other customers who use that filling station, then you may start wondering why the gas tank overflows when filling? Especially for your vehicle!

The gas tank overflows when filling mainly due to issues like gas nozzle problems in filling station, improper insertion of fuel dispenser while filling, filling speed set to high, pinched or kinked parts like fuel filler neck, breather hose or a vapor vent hose, stuck closed parts like anti-spill back valve, tank vapor vent valve, or charcoal canister vent solenoid, canister vent port blocked or filter clogged, overfilling of fuel tank, bad purge valve or even the vehicle parking under hot sun just before fuel filling.

If you are facing a similar problem and want a fix to get rid of the issue, then you are at the right place.

Here in this article, you will get to know the probable root causes of the problem which may help in pinpoint the problem areas by using the method of elimination. Here we go!

Before we proceed to discuss the topic of why the gas tank overflows when filling, it is prerequisite to understand two phenomena, first, is how does the gas nozzle know when to stop and the second, is how the venting system works in gas tank?

Table Of Contents

- 1 How Does The Gas Nozzle Know When To Stop?

- 2 How Does The Venting System Works In Gas Tank?

- 3 Gas Tank Overflows When Filling? Reasons And How To Fix!

- 3.1 Gas nozzle problems in filling station

- 3.2 Improper insertion of dispenser nozzle into the filler neck

- 3.3 Filling speed set to high

- 3.4 Fuel filler neck hose kinked

- 3.5 Breather hose Pinched

- 3.6 Anti-spill back valve stuck closed

- 3.7 Fuel tank vapor vent valve stuck closed/faulty

- 3.8 Vapor vent hose pinched or kinked

- 3.9 Charcoal canister vent solenoid stuck closed

- 3.10 Charcoal canister vent port opening blocked

- 3.11 Charcoal canister filter clogged

- 3.12 Overfilling the fuel tank

- 3.13 Bad evap purge valve

- 3.14 Parking vehicle under hot sun

- 4 Conclusion

How Does The Gas Nozzle Know When To Stop?

Typically, a gas nozzle auto shut-off feature works using the principle of venturi and has a complex mechanism and series of valves to enable the flow of fuel till the fuel level in the tank reaches the tip of the gas nozzle.

The venturi is an arrangement that has a converging portion, throat portion, and a diverging portion.

When the fuel flows through the gas nozzle and enters the converging portion and move towards the throat portion the velocity of fluid increases and the pressure of the fluid decreases, which means it creates a vacuum region at the throat portion.

This is based on Bernoulli’s equation; this is too technical! Isn’t it?

Generally, all gas nozzles have a sensor located at the tip of the nozzle and it is open to the atmosphere from the bottom side. This sensor is connected by a tube internally to the vacuum region (throat) via. a diaphragm valve, which controls the fuel outlet path.

While fuel filling, when the fuel level in the tank is much on the lower side, the sensor opening is unrestricted and allows suction of air due to vacuum and prevents vacuum build-up and diaphragm activation, hence the fuel flow is maintained.

But when the fuel level reaches the tip of the gas nozzle, the liquid fuel closes the sensor bottom opening and restricts the air suction.

This causes the vacuum to get build up inside the gas nozzle and triggers the diaphragm valve to close the fuel outlet path. This phenomenon is known as auto shut-off operation.

That is why when the fuel tank is about to get filled, the sensor senses it and cuts off the fuel supply.

How Does The Venting System Works In Gas Tank?

The fuel system plays an important role to keep the vehicle moving. The main function of the fuel system is to store the fuel tank without building up pressure or vacuum inside the fuel tank.

But at the same time it facilitates optimum utilization of fuel vapors and also to supply the liquid fuel to the engine without any leakage.

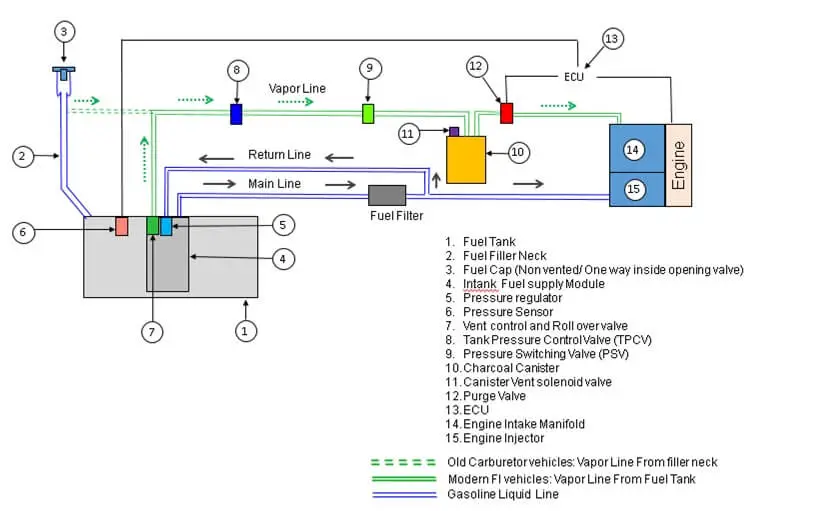

Several parts are involved in making a fuel system perform its intended function. There are two circuits in the fuel system.

One is a liquid circuit, to transfer the liquid fuel to the engine. It involves a fuel tank, fuel pump, fuel filler neck, fuel cap, fuel breather hose, and fuel outlet hose.

And the other one is the vapor circuit to handle the vapors getting generated inside the fuel tank. It includes a roll-over valve, vapor vent valve, fuel pressure sensor, charcoal canister, canister vent solenoid valve, purge control valve.

Usually in modern vehicles and in some of the old vehicles which have an evaporative emission control system, there is non vented fuel cap to control the escape of vapors generated inside the fuel tank which otherwise would find their way to the atmosphere.

So here the fuel vapors are passed through the roll-over and vapor vent valve and finally to the charcoal canister where the fuel vapors are adsorbed.

The vapors which are collected in the charcoal canister are sent to the intank manifold for combustion by the activation of the purge control valve which is connected to the charcoal canister. The purge valve is controlled by the vehicle ECU.

The function of the roll-over valve is to prevent the entry of liquid fuel into the vapor circuit or the charcoal canister in case the vehicle topples upside down or when the fuel level goes up in the fuel tank.

The role of the vapor vent valve is to maintain fuel vapor pressure inside the fuel tank and once it reaches a certain pressure, the vapor vent valve opens and relieves the vapor to the charcoal canister for adsorption.

Conversely, when the vacuum is generated inside the fuel tank, the outside air enters the charcoal canister AIR port and reaches the fuel tank to maintain the atmospheric pressure inside the fuel tank.

Thus the charcoal canister apart from doing the function of storing fuel vapors also helps in venting the fuel system to maintain the atmospheric pressure inside fuel tank.

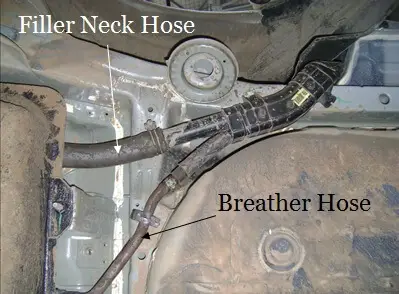

During fuel filling, the fuel enters the filler neck hose assembly which consists of the filler neck and breather hose which are connected to the fuel tank.

When the fuel enters the fuel tank, it shall displace an equivalent volume of air from the fuel tank.

But do remember that unless the air which is occupied inside the fuel tank is displaced to the charcoal canister or outside atmosphere in case of non ORVR system, the liquid fuel won’t be able to reach the fuel tank with ease.

Hence the fuel and gas nozzle would end up experiencing back pressure during fuel filling.

The rate at which the air is being displaced outside the fuel tank shall be more or less equal to the rate at which the fuel is being filled to ensure trouble-free fuel filling.

Gas Tank Overflows When Filling? Reasons And How To Fix!

Having understood the mechanism of gas nozzle working and basics of fuel system venting, it is time to deep dive into our main topic, why the gas tank overflows when filling?

Here is the list of probable root cause which would lead to this overflowing business. You may need to look for what is applicable in your case to zero in on the target area to work on.

Gas nozzle problems in filling station

The gas nozzle has many parts which need careful and frequent attention and needs to be serviced properly otherwise it would end up malfunctioning and affect its performance.

The result is that the gas pours out when filling the tank. This may be due to the issue with the sensor or some other part in the gas nozzle and may not be related to your vehicle or fuel system.

You may cross-check this problem by confirming whether other customers who use that filling station also face a similar problem? or can you comfortably fill the fuel at other filling stations?

If the answer to one or both of the above questions is No, then you need to look for issues in your vehicle, or is there any problem in the way in which you fill the fuel inside the tank.

If the issue happens at the same pump at the same station, then it’s the pump gas nozzle and not your vehicle!

Improper insertion of dispenser nozzle into the filler neck

Many times the gas tank overflows when filling only if you are doing improper insertion of the gas nozzle into the fuel filler neck.

The gas nozzle has to be inserted as deep into the filler neck as you can!

If the gas nozzle is just inserted a little bit into the filler neck, then, when the fuel level rises in the filler neck, the fuel will start overflowing through the gap between the gas nozzle and the filler neck before even the gas nozzle sensor senses to cut off the fuel.

Also, it is better to lower the back of the nozzle down while holding it completely into the tank, so that when the fuel gushes out from the nozzle, it goes straight into the neck instead of hitting the walls of the filler neck.

Otherwise, the fuel would either splash back onto the sensor triggering auto shut off, or the fuel spills back from the filler neck outwards.

Many times by adjusting the gas nozzle position slightly in or out and adjusting the angle of the gas nozzle while filling will prevent the gas from spilling out.

Usually, this depends on the filler neck design and the location of the bend in the filler neck.

Ensure that the dispenser nozzle doesn’t hit the anti-siphon feature, if any, provided inside the neck. After some trials, you would be able to figure out which position suits better for your vehicle.

Filling speed set to high

If the gas pours out when filling tank is the usual phenomena for you, then you may try reducing the speed at which the fuel is being filled by locking the dispenser to latch at an appropriate low position.

In some cases, the fuel filler neck design necessitates slow filling. This gives time for the air and gas vapor to escape out of the fuel tank via. the filler neck or vapor vent valve.

So you would not end up spilling the fuel all over when filling the tank to the brim.

This setting is more suitable if the gas dispenser nozzle doesn’t have a sensor to do an auto-shut off operation.

Fuel filler neck hose kinked

In some vehicles, you may observe that even though there is no pressure build-up in the tank on opening the gas gap, you may experience gas tank overflows when filling.

In that case, there is a high probability that the fuel filler hose through which the fuel is being filled is either squeezed or kinked owing to its shelf life or it might have got damaged from road debris, or a blown tire could also cause obstruction in the path of the fuel filler neck.

It is also possible that someone while siphoning fuel out of the filler neck, ended up leaving some small objects inside the filler neck, which is entangled inside the neck.

This causes a reduction in the opening area of the filler neck, so the rate at which the fuel is allowed inside the fuel tank may be lesser than the rate at which the fuel is being filled.

Hence the excess fuel which remains upstream of the kink will put back pressure in the filler neck and the pressurized fuel flow towards the gas nozzle and causes the gas to pour out before the gas nozzle sensor senses the fuel to shut it off.

So jack up your vehicle and thoroughly inspect the fuel filler hose to ensure it is free from kink and you may need replacement with new one if the kink is permanently deformed.

Breather hose Pinched

In most of the old vehicles without Onboard refueling vapor recovery (ORVR), there is a provision of a breather or venting hose connecting the fuel tank top to the filler neck to facilitate the escape of air and gas vapor to create space for incoming fuel.

The breather hose may get pinched off due to some reasons like during servicing the mechanic accidentally pinched the breather hose between some neighboring objects.

Then this breather hose restricts the escape of air which in turn prevents the free flow of liquid fuel into the fuel tank since air and vapor displacement is essential for the fuel entry into the tank.

This leads to improper ventilation of the fuel system, hence the fuel back pressure builds up inside the tank. Hence the gas pours out when filling tank.

So, ensure that no part of the breather hose is pinched off between surrounding parts.

Anti-spill back valve stuck closed

Generally, there is an anti-spill valve mounted at the bottom of the filler neck at the entrance of the tank. It is a flapper or one-way valve to allow fuel in but not out and operates by the same principle as a simple clip spring.

There may be some foreign matters which can get entangled at the spring, thus preventing the normal opening operation of the flapper valve and it may remain stuck closed.

This will not allow the fuel to enter inside the fuel tank which in the normal case will get open due to the gravity head of the fuel.

But when it is stuck open, there will be a huge pressure build up inside the filler neck and increases the back pressure and hence the gas tank overflows when filling.

You may need to remove the fuel tank to inspect this anti-spill back valve and check free movement of anti-spill back valve.

Fuel tank vapor vent valve stuck closed/faulty

In some vehicles equipped with onboard vapor refueling recovery, the fuel system is designed to prevent the escape of air vapor mixture during refueling by providing a narrow filler neck opening area.

A liquid seal is created that prevents vapor from escaping from the filler neck. In those vehicles, the fuel system venting solely depends on this vapor vent valve.

When the fuel reaches above the fuel tank vapor vent control valve, it closes to prevent the entry of liquid fuel into the vapor circuit, but it allows the vapor to exit when the fuel level comes down to a lower level.

But sometimes over some period, this vapor vent valve remains stuck closed or clogged or becomes faulty, so the vapor and air escape path gets blocked.

Again due to this there will be back pressure generation in the fuel tank which would lead to gas spitting back out of the tank while filling.

This vapor vent valve is usually located at the top of the fuel tank and it comes inbuilt with the fuel supply pump module or attached separately to the fuel tank.

In many vehicles, it can be accessed through the access window provided under the rear seat. Locate it and check whether it is functioning properly by blowing air through it and replace it with fresh one if required.

Vapor vent hose pinched or kinked

This will be a probable root cause especially when you feel that there is pressure build-up inside the tank while opening the fuel cap. You may hear some typical ‘HISS’ sound while opening the fuel cap.

The hose which connects the vapor vent valve to the charcoal canister might get pinched so the conditions become more or less the same as the faulty vapor vent valve.

The vapor or airflow path towards the charcoal canister is restricted or the gas vapor doesn’t escape to the canister and so the gas tank overflows when filling.

So get under the vehicle and look for the vapor hose which is connected to the charcoal canister and examine the entire length of the hose to confirm no pinching or kinking.

To ensure that the hose internal diameter is free from clogging, you may take out the hose and blow air at one end. The air shall flow freely and shall be felt at the other end., if not replace the hose with new one.

Charcoal canister vent solenoid stuck closed

The main function of charcoal canister vent solenoid is to maintain atmospheric pressure inside the tank when there is pressure generation and allow air inside the charcoal canister while purging the canister.

But when the canister vent solenoid valve is stuck closed due to some reason, it will not perform above both functions. This affects the venting of the fuel system, hence there is a likelihood of fuel spitting back out of the tank while filling.

To solve the problem at hand, you may essentially inspect the vent solenoid valve for glitches and replace it with a new one if required.

Charcoal canister vent port opening blocked

In some cases, the canister vent solenoid performs its function genuinely but when some foreign matter like mud and dust accumulates on the inlet of the vent solenoid valve, then the air can’t move in or out of the fuel system.

This affects the breathing of the fuel system to a greater extent and thus leads to fuel filling difficulty and the problems associated with that.

So, confirm that there is no buildup of foreign matters on the vent port opening and keep it clean.

Charcoal canister filter clogged

The charcoal canister filter performs the function of filtering out the air moving in and out of the canister. It also helps to keep the charcoal particles from entering into the purging system and further into the fuel injectors.

But over some period, due to vehicle vibration, the charcoal canister particles become fine powder and these filters may get clogged and would not allow natural venting of the fuel system.

So this also could be the reason for back pressure generation in the fuel tank and hence the gas spews out of tank when filling.

since this filter comes inbuilt with the charcoal canister, so you may need to replace the entire canister to get rid off faulty canister filter.

Overfilling the fuel tank

If you have the habit of overfilling your tank up to the brim of filler neck just to round off the decimal to the nearest dollar or to ensure maximum mileage of the vehicle in each filling, then chances are that the fuel may enter the vapor circuit and reaches the charcoal canister.

This is especially true if your vehicle is an old one wherein there is no roll-over or vapor vent valve to prevent the liquid fuel from entering into the canister.

The vapors are collected from the topmost point of the filler neck in older vehicles, so when you top it off the fuel finds its way to the charcoal canister.

Frequent tank overfilling, floods the charcoal canister and ruins the charcoal particles inside & clogs it. This causes the vapor saturation of the canister and the charcoal particles many times turns into a fine powder and loses their porosity.

This prevents the free movement of air across the canister and would need replacement of charcoal canister with a new one. Simply by checking the weight of the canister you may get to know the flooding of the canister.

This would result in fuel system venting problem as discussed earlier and thereby the backpressure generation and leads to gas tank overflowing issue when filling fuel.

You may also get a Check Engine Light (CEL) issue on the dashboard, indicating much more serious evaporative emission related risks which are frequently misdiagnosed and becomes a costlier affair.

So it is recommended to follow the idea of whenever the pump stops, you stop! When the fuel level is about to reach the tip of the gas nozzle, the sound and pitch of fuel filling changes, if you listen carefully. So you can be alert and deliberately under fill the tank if possible but do not overfill.

Bad evap purge valve

The purge valve plays a major role in utilizing the fuel vapor stored in the charcoal canister. During favorable engine operating conditions, the vehicle ECU sends a signal to activate the purge valve.

The purge valve is connected to the charcoal canister on one end and an engine air intake manifold on the other end.

Once the purge valve is activated, it opens and connects the engine vacuum to the charcoal canister to purge the vapors adsorbed inside the charcoal canister.

If the purge valve has gone bad then it fails in pulling the vapors away from the canister. This causes the saturation of the charcoal canister and ends up clogging it.

This affects the breathing of the fuel system and the associated back pressure generation, hence the gas tank overflows when filling.

So you may need to check the effectiveness of the purge valve and if found faulty replace it with a new one.

Parking vehicle under hot sun

We all know that gasoline is a highly volatile liquid. Whenever there is an increase in fuel temperature, gasoline’s phase changes from liquid to vapor.

This increases the vapor pressure of the fuel inside the tank and thus tank’s overall internal pressure increases.

So whenever you park the vehicle under the hot sun, the fuel temperature increases as per ambient temperature variations and it increases the tank pressure.

Since the filler neck is connected to the fuel tank, this creates back pressure inside the neck. If you take the vehicle which is parked under the hot sun for refueling, then be ready to face the back pressure of vapor.

This causes the gas tank to overflow when filling. So as far as possible, it is better to park your vehicle inside the garage, if you have one, to maintain atmospheric pressure inside the fuel tank.

Conclusion

There are new evaporative emission regulations that surface out now and then, to control the environmental pollution caused by the gas vapors generated inside the tank and those that escape while refueling.

We just discussed the probable root causes for the gas tank to overflow when filling. But the applicability of a particular cause depends on the design of the fuel system in your vehicle, refueling speed, style of filling, and much more.

What is applicable to you, need to be evaluated carefully by checking each root cause. In almost all cases, the issue is back pressure getting build-up in the filler neck and liquid fuel touching the sensor.

If you are able to figure out the cause of this problem, your problem is half solved!

Hope the information above empowers you with the knowledge of what all may go wrong and supports you in fixing the problem. Happy motoring!

References

https://www.quora.com/How-can-I-prevent-my-cars-gas-tank-from-overflowing-when-filled

https://community.cartalk.com/t/gas-tank-overflows-when-filling/60241

https://www.fitfreak.net/forums/general-fit-talk/35553-ever-have-gas-overflow-when-filling-up.html

https://www.gm-volt.com/threads/gas-pump-didnt-stop-gas-overflowing-out-of-car.77618/