The fuel system of a vehicle has various components that help in supplying liquid fuel at desired pressure and flow rate to the engine for ensuring proper performance of the vehicle.

The components include the fuel pump, fuel tank, fuel pressure regulator, fuel filter, and fuel supply hoses to name a few.

You might have come across the situation of improper vehicle driving conditions like vehicle rough idling, poor throttle response at acceleration and engine jerking at WOT (Wide Open Throttle), etc.,

Often the root cause of these vehicle driving problems is related to issues in either one of the fuel system components or engine-related parts.

The former is easy to identify and fix and the latter may require professional technicians depending upon the severity of the issue and the criticality of the parts involved.

Out of many fuel system components, it is the fuel pressure regulator which plays a critical role in ensuring adequate fuel delivery pressure and flow rate.

The fuel pressure regulator is connected to the intake manifold vacuum through a vacuum hose for maintaining the fuel pressure difference between the intake manifold and fuel pressure and to adjust the air-fuel mixture ratio depending upon the throttle input.

If you are noticing that the fuel pressure regulator vacuum hose disconnected, then you are bound to experience vehicle performance issues.

If you are facing a vacuum hose disconnection problem and looking for the reason and solutions, then stay tuned and continue reading. Here, we will cover all details required for fixing the problem.

Table Of Contents

- 1 How Does Fuel Pressure Regulator Works?

- 2 Why Is a Vacuum Line Attached To a Fuel Pressure Regulator?

- 3 What Happens When Fuel Pressure Regulator Vacuum Hose Disconnected?

- 4 What Are The Cause Of Fuel Pressure Regulator Vacuum Hose Disconnection?

- 5 How To Prevent Vacuum Hose Disconnection?

- 6 What Will Happen If a Vehicle Has a Leaky Vacuum Diaphragm On The Fuel Pressure Regulator?

- 7 How To Test Leaky Diaphragm On Fuel Pressure Regulator?

- 8 Conclusion

How Does Fuel Pressure Regulator Works?

The fuel pressure regulator plays an important role in maintaining certain fuel pressure across the injectors for ensuring fine atomization of fuel at injector holes.

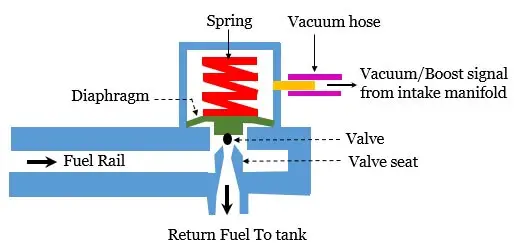

The fuel pressure regulator typically has a spring, diaphragm, and valve seat arrangement.

It also has 3 nozzles, one is connected to the fuel rail, the second one to the fuel return line, and the third one to the intake manifold in case of vacuum modulated fuel pressure regulator.

Inside the fuel pressure regulator, the spring is assembled in compressed condition above the diaphragm. The diaphragm is connected to a valve that closes against a valve seat leading to the fuel return line.

Two types of fuel pressure regulators that are used in vehicles based on the fuel system design.

Fuel pressure regulator with no vacuum chamber

In the case of a non-vacuum modulated fuel pressure regulator i.e. one with no connection to intake manifold vacuum, certain pre-defined pressure is required to compress the spring to lift the diaphragm off its valve seat.

The spring rate of the fuel pressure regulator ensures the minimum fuel pressure required for the diaphragm valve to open.

Once the fuel pressure exceeds desired pressure, the spring gets compressed and the valve uncovers the valve seat and leaks back fuel to the fuel tank via. the fuel return line.

When the leak back happens, it will reduce the fuel pressure until it reaches desired pressure in the fuel supply hose wherein further fuel leak back will be stopped.

So once again the pressure starts increasing till it regains working pressure and this cycles keeps on continue to maintain fuel pressure in the system.

Vacuum modulated fuel pressure regulator

In this case, the fuel pressure regulator has a separate vacuum chamber that is connected to the intake manifold vacuum.

When the intake manifold vacuum is more (suction), it lifts the spring to take off the diaphragm valve against the valve seat.

This increases the opening area of the fuel return port and more fuel returns to the fuel tank. Hence the fuel pressure in the fuel rail gets reduced.

When the intake manifold vacuum is less or at positive pressure, it pushes the spring and so the diaphragm towards the valve seat thereby closing the valve seat partially or completely.

Since the fuel return outlet opening area decreases, less fuel would get returned back to the fuel tank.

This builds up pressure in the fuel rail and the fuel pressure increases accordingly.

Actually, it is the restriction to the fuel flow that causes the fuel pressure to increase.

Why Is a Vacuum Line Attached To a Fuel Pressure Regulator?

The fuel demand of the engine varies depending upon the driving conditions and throttle input given by the driver.

So the air-fuel ratio (AFR) that needs to be maintained for a good vehicle performance varies accordingly.

The ideal air-fuel ratio i.e. stoichiometric AFR ratio is 14.7:1. This ensures complete combustion of the fuel thereby leaving no unburnt hydrocarbons in the exhaust tailpipe.

But during vehicle running, this ideal AFR could not be achieved due to the shorter time available for combustion of the fuel.

The gasoline engines usually run with the AFR in the range of 9:1 to 20:1. When the AFR is less, the engine is said to be running rich which produces more energy or power. This will be the situation in hard acceleration or at WOT condition.

When the AFR is more, the engine runs lean and develops relatively less power. This state may exist in an idling condition.

To cater to varying A/F ratio demand, the fuel pressure in the fuel rail or at the injectors needs to be adjusted based on driving conditions and throttle input.

To achieve that, the fuel pressure regulator is connected to the intake manifold vacuum through a hose. Hence during idling conditions, since the throttle plates are fully closed, the vacuum in the intake manifold is maximum.

This max. vacuum pulls the spring in the pressure regulator upwards and displaces the diaphragm valve off its valve seat to return the fuel to the tank and thereby reducing the fuel pressure.

But during WOT conditions, since the throttle plates are fully open, the vacuum in the intake manifold is least, hence the spring is pushed downward.

So the diaphragm in turn partially closes the return line outlet. This leads to an increase in the fuel pressure in the fuel rail.

In vehicles with the turbocharger, the intake air is compressed by the turbine that is driven by the exhaust gases, and pressurized air is sent to the intake manifold.

So during boost conditions, when the intake manifold pressure is maximum, the spring is pushed down to the dead position.

Due to this, the diaphragm valve closes fully and the fuel return is almost blocked. This increases the fuel pressure to the maximum and causes rich AFR condition that is required for developing max. power output. For example, if the base fuel pressure is 40 psi, it will be 55 psi at 15 boost.

In all of these condition, the pressure difference between fuel pressure and the intake manifold is tried to be kept constant.

Imagine the fuel injector spray pattern, if the intake manifold pressure and fuel pressure are the same in vehicles having a boost.

In that case, the fuel instead of getting atomized, will simply dribble out of the injector and will not produce complete combustion.

Hence by connecting the fuel pressure regulator to the intake manifold by a hose, the boost pressure helps in increasing the fuel pressure accordingly.

What Happens When Fuel Pressure Regulator Vacuum Hose Disconnected?

Often it is observed that the people report the issue of fuel pressure regulator vacuum hose disconnected and this phenomenon is always accompanied by the vehicle driving issues.

You would see a thick pool of oil all around the FPR and the rail area. But one should know what happens if the vacuum line falls out off your fuel pressure regulator.

This is because sometimes people get accustomed to compromised vehicle performance without knowing the effect of no vacuum supply to fuel pressure regulators.

Below are the effects of removing the vacuum line from the fuel pressure regulator.

Engine hard starting

If the vacuum hose is disconnected, the atmospheric pressure would be acting on the spring side vacuum chamber of the pressure regulator and the fuel pressure instead of getting reduced will be higher in idling conditions.

So you may experience an engine starting problem due to lower AFR at vehicle starting condition or throttle plate closed state.

Engine stalling

For the proper fuel combustion to take place, the AFR has to be within a suitable range.

If the vacuum hose is unplugged from the pressure regulator, a rich air-fuel mixture will be maintained even in low fuel demand conditions like POT condition (partial open throttle)

Even if the engine starts it would not be able to sustain the performance and it may stall at any time due to the imperfect combustion cycle of fuel.

The Rich air-fuel mixture at undesired driving conditions would also damage the engine parts thereby will affect its performance.

Vehicle rough idling

Typically, the WOT fuel pressure is set when atmospheric pressure prevails at the intake manifold, hence the fuel pressure reduces with the manifold vacuum.

But when the pressure regulator vacuum hose is disconnected, this won’t happen.

Since the fuel pressure remains high irrespective of throttle position, the AFR would be constantly maintained towards rich conditions even in idling conditions.

This rich air-fuel mixture would affect the idle and would shoot the idle RPM and causes the engine to run rough during idling.

You could experience engine revs up and down unevenly without even providing throttle input during idling. These issues won’t get fixed until you connect the vacuum hose to fuel pressure regulator.

Check Engine Light

Since the air-fuel mixture is affected due to the removal of a vacuum hose from the fuel pressure regulator, your vehicle emissions go for a toss and you would fail the emission test.

Usually, idle emissions are tough to achieve in any vehicle. But if the AFR at idle is affected by the disconnected vacuum hose from the fuel pressure regulator, then the emission goes out of the roof.

You also would get a check engine light on your dash which needs to be fixed before it starts damaging other engine parts.

Poor throttle response

If the fuel pressure regulator vacuum hose is disconnected, since the engine could run relatively lean at high throttle conditions, the fuel pressure will be comparatively less in acceleration condition and it won’t be the way it should be.

You would feel that the vehicle is struggling to accelerate since the fuel pressure will not be available as required.

Even in the case of boost condition, the increased intake manifold pressure would not get applied to the fuel pressure regulator’s vacuum chamber and AFR would not be towards rich conditions.

So you will not get the boost performance and the fuel pressure will remain average.

What Are The Cause Of Fuel Pressure Regulator Vacuum Hose Disconnection?

Rubber hose aging

The rubber is the most widely used material for the vacuum hose. But the problem with the rubber material is that it would lose its mechanical elasticity property and undergoes compression set and slowly works its way off over some period of usage.

The rubber hose’s inner diameter initially would fit tight on respective nozzles on the pressure regulator or intake manifold.

But after some vehicle mileage, the interference of the rubber hose over its mating part will get reduced and often gives off the sealing joint. Hence the vacuum hose gets unplugged from the fuel pressure regulator and the hose needs to be replaced with a new one to fix vehicle issues.

Engine vibration

Once the interference between the vacuum hose inner diameter and the corresponding mating part reduces and it fits loose on respective nozzles, any vibration exerted by the engine or road-induced excitation forces would try to rip off the hose. So the vacuum hose falls off from your pressure regulator.

Boost pressure

If the vehicle has a small engine but with a big turbo, then at boost spike, high intake manifold pressure would be applied to the vacuum hose joint of the fuel pressure regulator.

This would try to slip off the vacuum hose from the pressure regulator nozzle to disconnect it.

How To Prevent Vacuum Hose Disconnection?

If you notice that your vehicle’s fuel pressure regulator vacuum hose is disconnected, you may try the below fixes to avoid such future events.

Use spring band Or worm clamps

The Spring band clamps are available in any auto hardware shop to hold on the vacuum hose tightly to the fuel pressure regulator. Since the spring band clamps are suitable for typical hose OD, care to be taken while selecting it, otherwise it may fit overtight or loose.

These clamps usually sustain huge pressure ranging from 45 to 70 psi depending upon the design.

The worm clamps are suitable for a range of vacuum hose outer diameter, so it will perfectly suits the given application.

If the clamps are not readily available, then in that case you may use a zip tie or cable tie as a temporary measure, till you find the suitable clamps for your vacuum hose

Use rigid vacuum hose

It is recommended to use a reinforced rubber hose that doesn’t undergo a compression set so the interference fit between the hose and the corresponding nozzle on the regulator stays put.

It is necessary to select the correct size vacuum hose for ensuring a reliable seal joint otherwise even after replacing the vacuum hose you may encounter repeat events.

Technically speaking there must be at least 10% interference between the vacuum hose inner diameter and the nozzle outer diameter for a good sealing joint.

In the absence of spring band clamps, the percentage interference of 20% can be maintained to ensure leak proof joint.

What Will Happen If a Vehicle Has a Leaky Vacuum Diaphragm On The Fuel Pressure Regulator?

If you find any gasoline traces inside the vacuum hose, it confirms that the pressure regulator diaphragm is damaged and the fuel is leaking past the diaphragm into the intake manifold via. vacuum hose.

During idling conditions, if a vehicle has a leaky diaphragm then fuel would enter the vacuum hose due to the suction pressure prevailing in the intake manifold.

Hence the vacuum applied will be less and the pressure regulator spring and diaphragm arrangement won’t be retracted fully from the outlet valve seat.

This reduces the fuel discharge to the return line and thereby increases the fuel pressure in the fuel rail.

Fuel pressure could not be maintained as required and the engine would run rich and the corresponding AFR would not be suitable for idling conditions.

This gives rise to vehicle rough idling, engine jerking, vehicle hard starting, sluggish engine response, and many other driving performances related problems.

A leaky vacuum diaphragm is akin to removing a vacuum line from a fuel pressure regulator and you would end up with the same vehicle symptoms as the latter case.

People often ask, can a fuel pressure regulator cause a vacuum leak? Yes. The diaphragm in the pressure regulator may get torn off & would leak vacuum.

Resulting in more fuel pressure at idling conditions and comparatively less fuel pressure in acceleration conditions than it should be. Both are not the desired situation for engine operations.

The vehicle performance problem will persist until the fuel pressure regulator is replaced with a new one.

How To Test Leaky Diaphragm On Fuel Pressure Regulator?

Apart from noticing the fuel traces in the vacuum hose, we can confirm a leaky vacuum diaphragm by checking the actual fuel pressure in the supply line.

Connect the pressure gauge on the Schrader valve of the engine injectors, and then crank the engine and leave it for about 1 minute.

Note down the fuel pressure reading on the gauge and turn the car off and watch the pressure gauge thereafter.

If the pressure doesn’t maintain and drops immediately, then it means that the diaphragm has turned leaky and the time has come to replace the faulty fuel pressure regulator with a new one.

Conclusion

The vacuum hose connection between the fuel pressure regulator and intake manifold plays a vital role in maintaining the air-fuel mixture ratio at different driving conditions, engine speed, and load cases.

This connection always ensures and maintains a constant pressure difference between the intake manifold and the fuel pressure in the rail, thereby ensuring desired AFR and proper fuel combustion and hence the vehicle performance.

If the vacuum hose is observed to be disconnected, it shall be reinstated to its original condition to avoid erratic vehicle performance and engine emissions.

In the event of a leaky vacuum diaphragm on the fuel pressure regulator, the vehicle would behave as bad as disconnected vacuum hose condition and in addition, fuel droplets can be observed in vacuum hose pipe.

It is recommended to use spring band clamps which provide good radial sealing pressure at the vacuum hose joints or you may need to replace the vacuum hose with a new one if it is observed to be damaged.

Hope with the above information you would be able to fix the problem associated with the fuel pressure regulator vacuum hose disconnection and would same efforts and time in finding the right solution.

Happy Motoring!

References

https://www.evoxforums.com/threads/vacuum-line-for-fuel-pressure-regulator-disconnected.18366/

Articles You May Like To Read

Car Won’t Start After Fuel Pump Replacement. All You Need To Know!

Fuel Pump Not Priming? Reasons And Solutions To Fix It!

Fuel Pump Runs Continuously With Key On? 9 Causes And Solution To Fix It!

Fuel Pump Primes But No Pressure? Everything you Need To Know!